The 253 (253A) series openable current transformer adopts a compact structural design, uses high magnetic permeability soft magnetic materials and high-quality enameled round copper wire, and is produced by combining ultrasonic welding technology. Compared with similar products, it has the characteristics of small size, high precision and light weight. The product shell is made of environmentally friendly flame-retardant PC/ABS alloy engineering plastics, which has high strength, strong impact resistance and firm fixation.

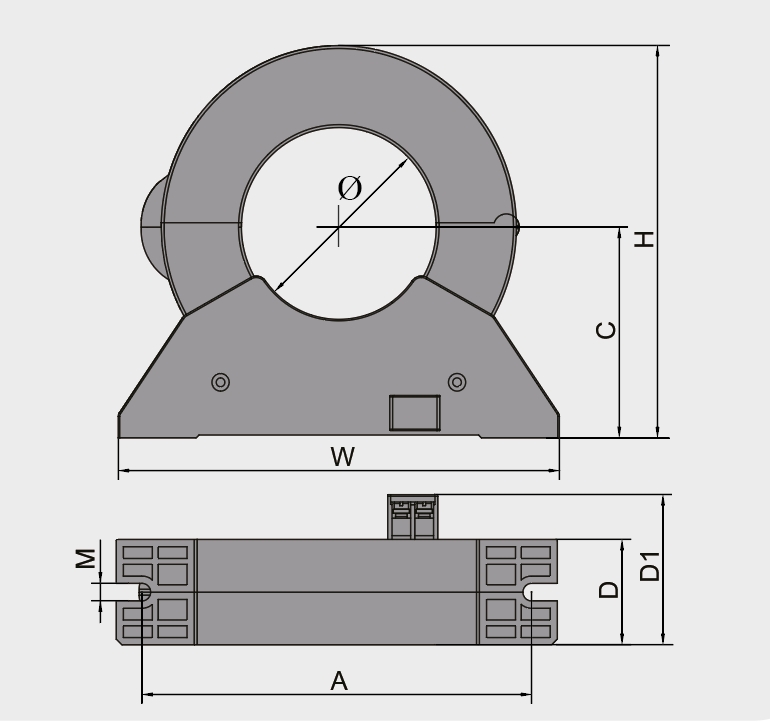

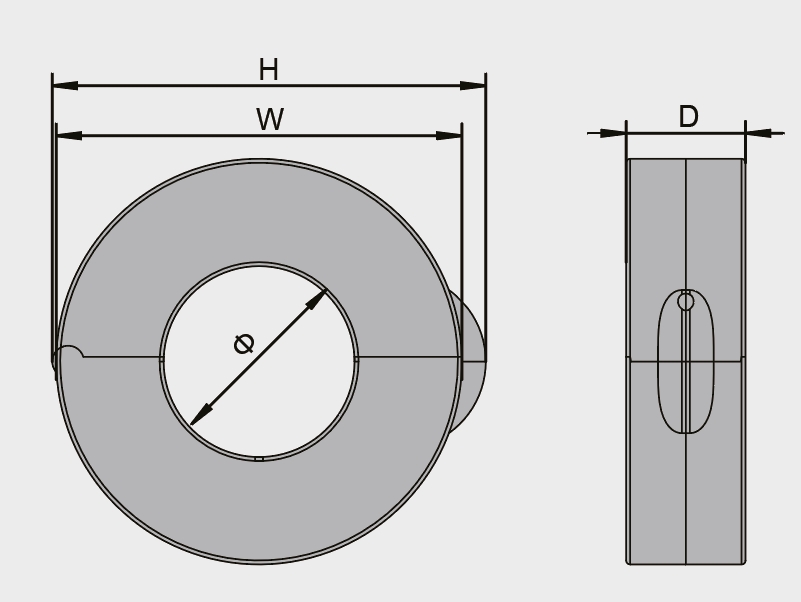

The 253 (253A) series openable current transformer adopts a compact structural design, uses high magnetic permeability soft magnetic materials and high-quality enameled round copper wire, and is produced by combining ultrasonic welding technology. Compared with similar products, it has the characteristics of small size, high precision and light weight. The product shell is made of environmentally friendly flame-retardant PC/ABS alloy engineering plastics, which has high strength, strong impact resistance and firm fixation.In terms of structural design, the product adopts bolt fixing method, and the fixing structure is firm and reliable. And the fixing bolts and nuts are built-in. Even if the product is installed in a complex environment, there is no need to worry about the fixing bolts falling off the product, which greatly reduces the trouble of dropping accessories during installation. The fixed base and the transformer body adopt a split design. According to needs, two different installation methods can be used. It has stronger adaptability to the installation environment.

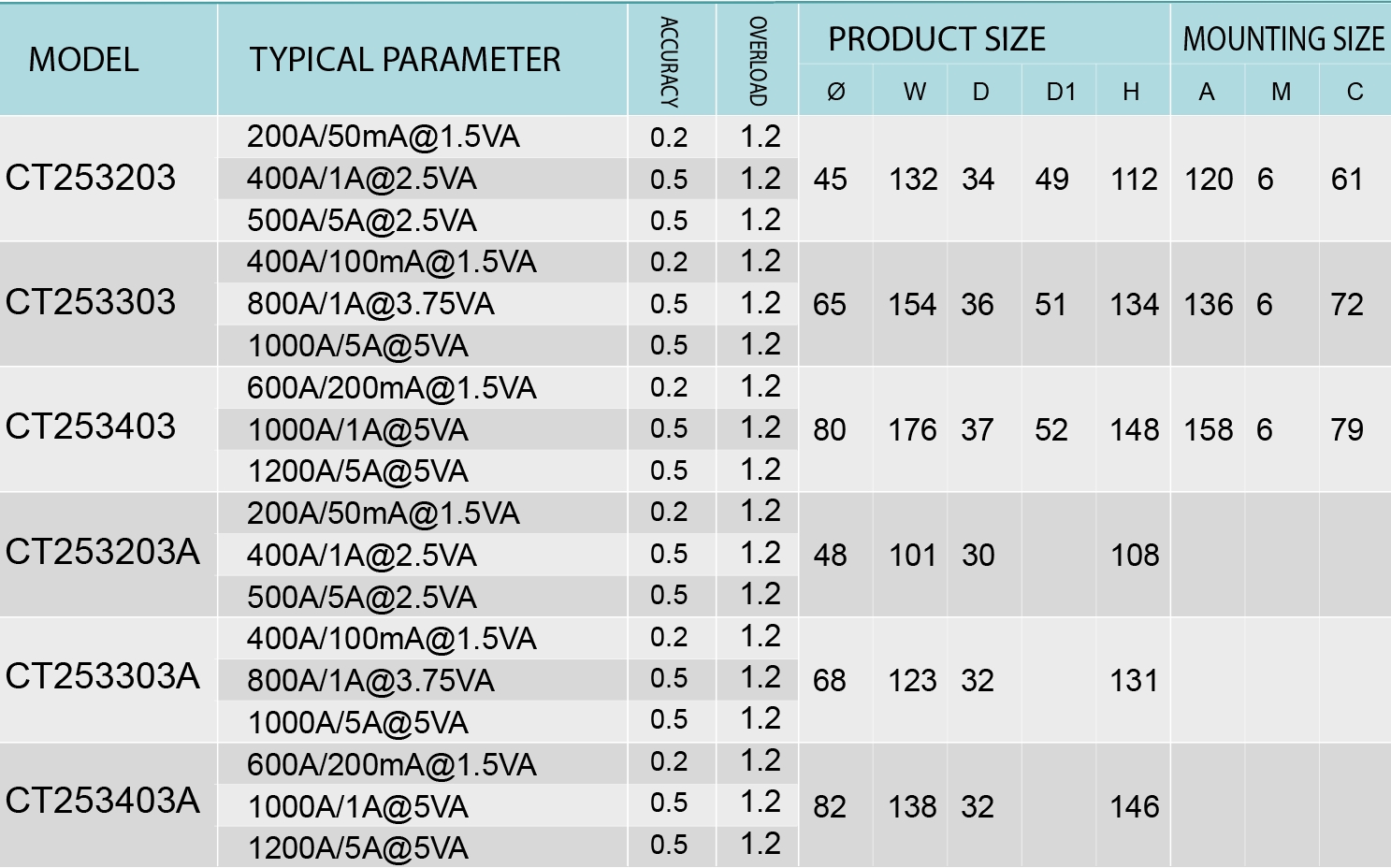

This series of products has 3 size specifications, which can measure cables with a current range of 100A-1200A. According to the requirements, the accuracy can be 0.2, 0.5, 1.0, etc. The secondary output signal can be a standard current of 5A/1A or a small signal current of mA level.

This series of products does not contain an open circuit protection part. During installation, the secondary circuit needs to be well connected before installation. During and after installation, the secondary output of the transformer is not allowed to be open.

Since larger soft magnetic materials can be used, the product can be applied to busbar energy extraction. When the current is less than 10A, it can output a power of more than 100mW. And under high current conditions, the working noise generated by the saturation of the core is extremely small.

The product shell color can be produced according to the customer's specified color to meet different color schemes.

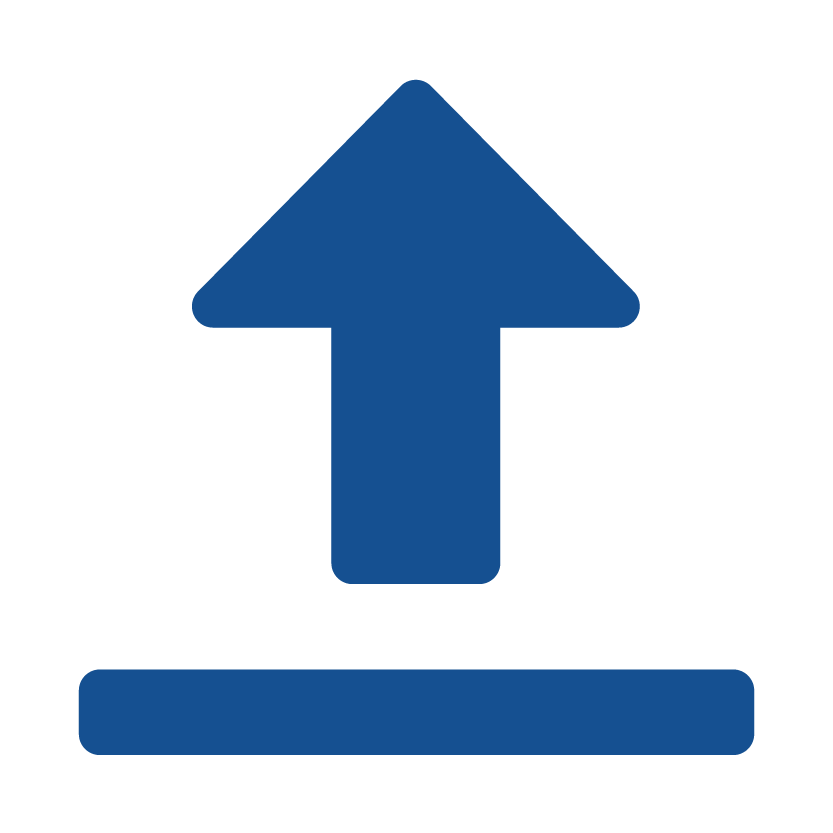

Naming:

Color code:

0: black; 2: red; 6: blue; 8: gray;

The shell color specified by the customer is coded and classified according to the main color of the color system;

Normal use and installation conditions:

Installation location: Indoors.

Ambient temperature -20℃~+50℃.

Ambient humidity The recommended relative humidity is not more than 80%.

Altitude Not more than 3000m.

Atmospheric conditions There is no serious pollution, corrosive and explosive media in the atmosphere.

No environment with significant frequent vibration and impact.

Storage temperature -30℃~+75℃.

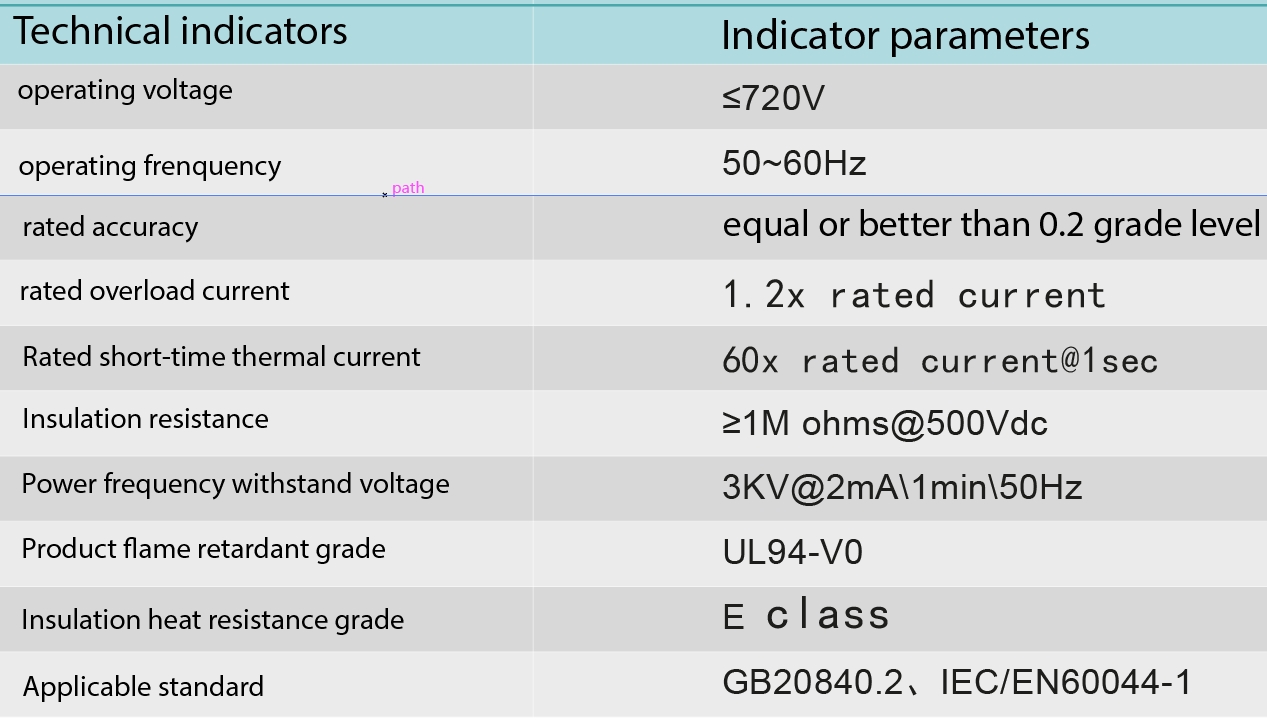

General technical indicators:

Product Specifications Table:

Add:Sanqing Century Wealth Center, Tianchen Road, Lixia District, Jinan City

Email:export@bojingchina.com

Fax:0531-85708558