Product Center

Precision Sensors

Hall Current Sensors

Hall current sensors are divided into open-loop Hall current sensors and closed-loop Hall current sensors, while Hall voltage sensors generally adopt a magnetic balance type, i.e. a closed-loop structure. Compared with the two structural methods, the open-loop Hall sensor has a simple structure and low cost; the closed-loop Hall sensor has higher detection accuracy than the open-loop Hall sensor, but the cost is also high and the process is more complicated than the open-loop Hall sensor.

In applications where the requirements are not too high, open-loop Hall sensors can be selected to save costs; applications with higher requirements can use closed-loop Hall sensors to improve accuracy.

In applications where the requirements are not too high, open-loop Hall sensors can be selected to save costs; applications with higher requirements can use closed-loop Hall sensors to improve accuracy.

The schematic diagram of the open-loop Hall current sensor is as follows:

Schematic diagram of open-loop Hall current sensor

When the measured current, that is, the primary current IP (Primary Current) flows through a long wire, as shown in Figure 3-3. The primary current IP will generate a magnetic field around the wire in a clockwise direction, and the magnitude of the magnetic field B is proportional to the magnitude of the current. The magnetic field excited by the primary current gathers in the magnetic ring and is added to the Hall element through the air gap. At this time, a Hall voltage UH will be generated on the Hall element. This voltage signal passes through the subsequent amplifier circuit and conditioning circuit to output a voltage Vout that is proportional to the magnitude of the magnetic field B, that is:

The output Vout of an ordinary Hall current sensor is generally between 0.5V and 4.5V. The disadvantage of an open-loop Hall current sensor is that its measurement range, i.e., the value of the primary current IP and the bandwidth (Frequency Bandwidth), are subject to certain limitations. In this application, the Hall element is a magnetic field strength detector, which detects the magnetic induction intensity in the air gap of the magnetic core. As the current increases, the magnetic field strength also increases, and the magnetic core may reach saturation. At the same time, as the frequency increases, the eddy current loss and hysteresis loss in the magnetic core will also increase. These will affect the measurement accuracy. In order to avoid these adverse effects, some improvement measures can be taken, such as selecting a magnetic core material with high saturation magnetic induction intensity, making a multi-layer magnetic core, and using multiple Hall elements for detection. However, this increases the manufacturing cost and the accuracy is not ideal. Therefore, closed-loop magnetic balance Hall voltage and current sensors began to appear.

The figure above shows the schematic diagram of a closed-loop Hall current sensor. A closed-loop Hall current sensor, also known as a magnetically balanced Hall current sensor, is also called a compensated sensor, in which the magnetic field generated by the primary current IP at the magnetic ring is compensated by the magnetic field generated by a secondary coil current, and the compensation current IS accurately reflects the primary current IP, that is,

In the formula, NS refers to the number of turns of the secondary compensation coil, and NP refers to the number of turns of the primary wire passing through the magnetic ring. Usually NP=1, then the compensation current, that is, the output current is equal to:

The entire model of the negative feedback automatic compensation current sensor is roughly composed of a magnetic core (magnetic ring), a Hall element, an amplification and conditioning circuit, a secondary compensation coil, a feedback link, and an external measurement resistor. Compared with the open-loop Hall current sensor, it can be found that the closed-loop type has a secondary compensation coil with a number of turns NS wound on the magnetic core, and an amplification feedback adjustment is connected to the output end of the amplifier. As can be seen from the figure, the output of the sensor is a current signal Is. When using a Hall sensor, we must connect an external measurement resistor Rm to obtain a voltage signal.

The specific working process of the closed-loop Hall current sensor is as follows: when a current IP passes through the primary side, a magnetic field will be excited around the wire, and the energy-gathering magnetic ring will gather most of the magnetic energy together, and the magnetic field will be vertically added to the Hall element, thereby generating a weak Hall voltage HU. Since the value of the Hall voltage is very small, it needs to be amplified by an amplifier before it can drive the transistor of the subsequent stage. Since the switch tube of the subsequent stage already has a positive voltage between the collector and the transmitter, when the amplified Hall voltage is added to the base, the switch tube is turned on, and a compensation current Is is obtained from it.

This current then generates a magnetic field through the secondary compensation coil with a number of turns NS. This magnetic field is exactly opposite to the magnetic field generated by the measured current, thereby compensating the original magnetic field and gradually reducing the output voltage UH of the Hall element. When Is*Ns=Ip*Np, Is no longer increases. At this time, the Hall device plays the role of indicating zero magnetic flux. At this time, the size of Ip can be measured by the size of Is, that is:

The primary current size can be obtained.

Due to the working principle of the Hall device and the structure of the Hall sensor, the Hall sensor can not only detect DC current, but also AC current, or pulse current, etc.

The working principle of the Hall voltage sensor is similar to that of the closed-loop Hall sensor. First, a primary winding needs to be added to the sensor. At the input end of the primary winding, a voltage divider and current limiting resistor are added to convert the high voltage of the primary side into an appropriate current through the voltage divider and current limiting resistor. Then the converted current flows through the primary winding of the Hall sensor, which is equivalent to the primary input current of the Hall current sensor. The subsequent working principle is the same as that of the Hall current sensor.

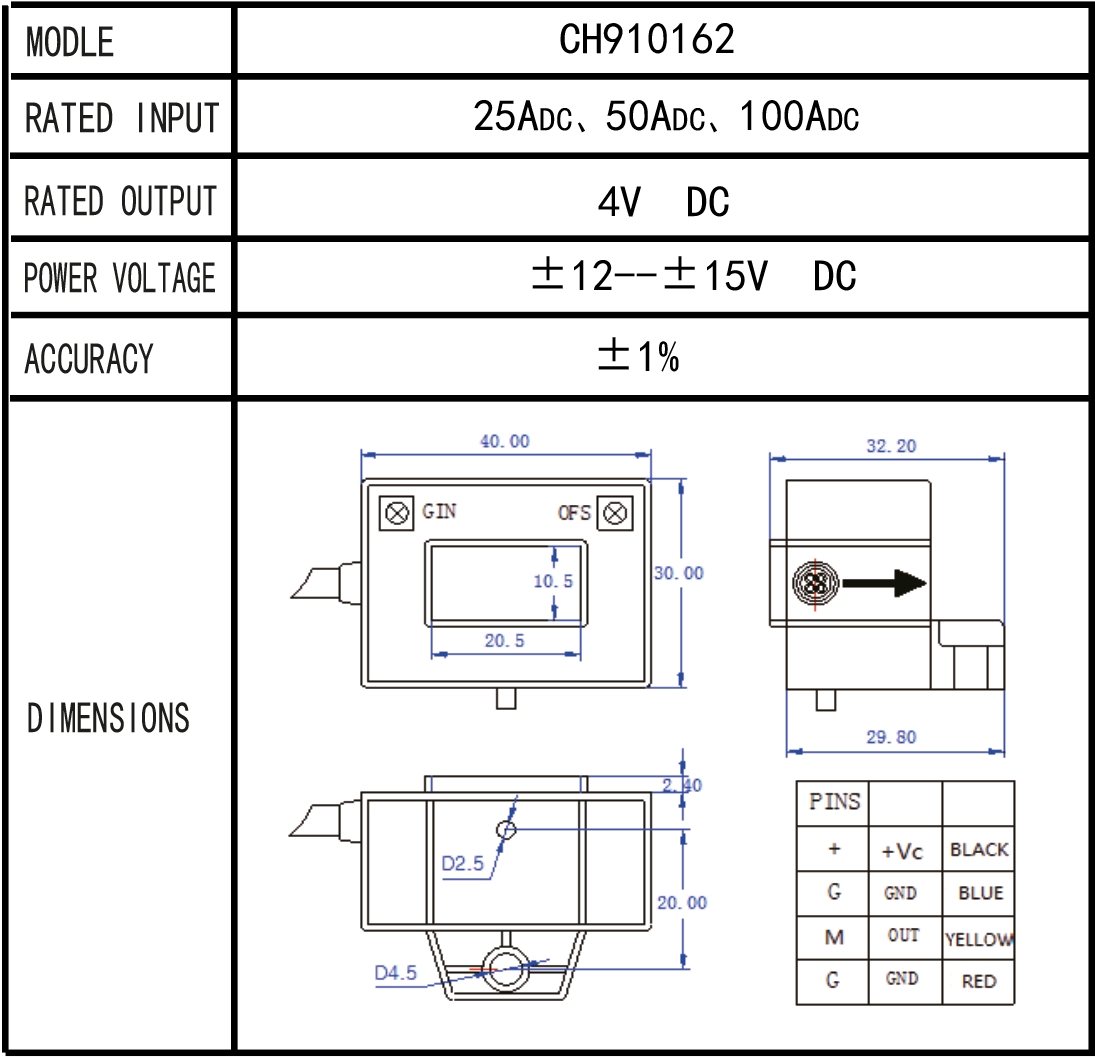

The Hall sensors currently produced by the company include open-loop Hall current sensors, closed-loop Hall current sensors, Hall voltage sensors and other products. The current that can be detected ranges from a few amperes to thousands of amperes. The output modes include pin output, plug-in terminal output, and lead output.

This series of products uses high-quality imported Hall devices, and uses more reliable industrial-grade products for key components of the circuit, which greatly guarantees the stability and reliability of the products. Some products use precision constant current technology and linear temperature compensation technology to convert them into standard tracking voltage output; they have the characteristics of high precision, high isolation, low power consumption, low drift, wide temperature range, and strong anti-interference ability.

According to needs, the product can be packaged in a technical shell with better anti-interference, anti-impact and anti-vibration capabilities.

The output signal of the product can be changed according to the design, and the output voltage and current basically meet the design requirements.

It should be noted that the power supply of the sensor should be wired strictly in accordance with the requirements of the specification book, and the polarity must not be connected incorrectly, otherwise the sensor may be burned out.

features :

*High precision and good linearity

*Strong overload capacity, can be 5 times/10 times the rated current according to needs

*Strong anti-interference ability, customizable metal shell

*Wide bandwidth, fast frequency response

*Compact design, small size and beautiful appearance

*Good consistency and excellent interchangeability

Naming:

Color code:

0: black; 1 brown 2: red; 6: blue; 9 white;

The shell color specified by the customer is coded and classified according to the main color of the color system;

Normal use conditions

Add:Sanqing Century Wealth Center, Tianchen Road, Lixia District, Jinan City

Email:export@bojingchina.com

Fax:0531-85708558

Copyright © 2024 Shandong Bojing Intelligent Technology Co., Ltd. All Rights Reserved.

鲁ICP备19065564号-1